Topic areas

Contract assembly

OEM manufacturer

Assembly of components

Component assemblyAssembly production

Component assembly mechanical engineering

Device assembly

Cable assembly

Micrograph analysis

Crimping machine

Assembled cables

Cable crimping

Cable assembly Germany

Confectioned cables

Individual cable assembly

Cable assembly online

Cable assembly electrical engineering

Cable harness production

Cable harness manufacturer automotive

Electrical assemblies

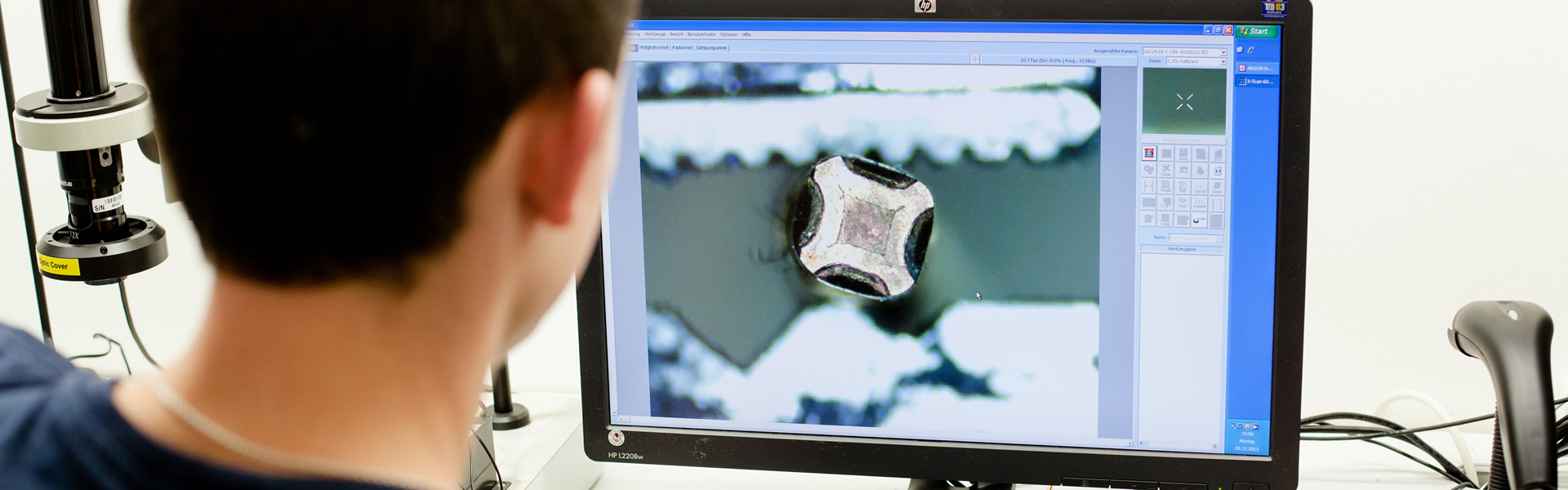

Micrograph analysis checks the quality

Play it safe with micrograph analyzes

Cables transmit signals or energy. They have to function reliably and without interference for a long time. This requirement applies to every cable - from the medical technology sector as well as for the automotive industry. As a service provider for cable assemblies, in-Tec Bensheim produces shielded and unshielded cables, multi-core special cables, cable harnesses, data and communication lines as well as round and flat strands.

Microsection examination: microscopically fine

Whether strand cores or crimp contacts are of the required quality, for example, is monitored in our grinding laboratory. A microsection examination provides microscopic information about the quality. Among other things, we investigate how evenly a crimped contact was pressed and whether it is gas-tight. The more optimal the crimping, the lower the resistance of the line. The behavior in the event of wear or due to temperature fluctuations can also be analyzed in this way. Control standards include checking the strand cores or the crimp height. In consultation with the customer, in-Tec Bensheim creates a test processes or a test plan that takes all relevant standards into account and constantly documents production.

A trustworthy partner for cable assemblers

Not every cable assembly company has its own grinding laboratory. in-Tec Bensheim provides collegial and reliable support to companies in the industry in ensuring their product quality or testing the functionality of their crimping tools. A micrograph analysis can be used to show whether a device is correctly set or needs maintenance.