Topic areas

Contract assembly

OEM manufacturer

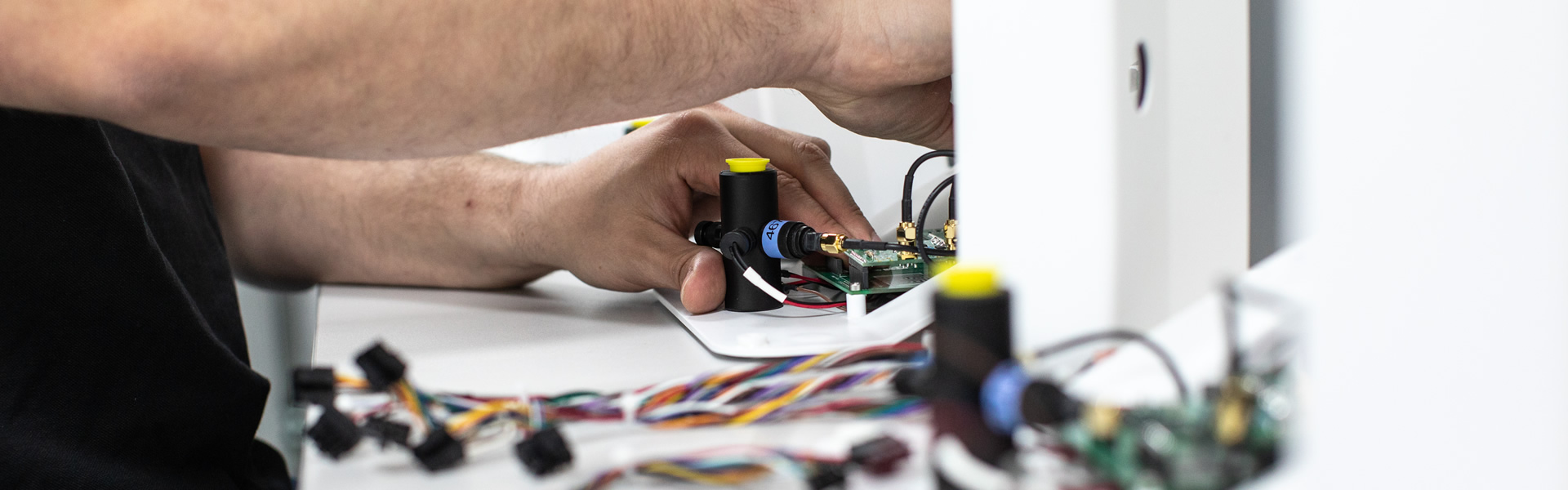

Assembly of components

Component assemblyAssembly production

Component assembly mechanical engineering

Device assembly

Cable assembly

Micrograph analysis

Crimping machine

Assembled cables

Cable crimping

Cable assembly Germany

Confectioned cables

Individual cable assembly

Cable assembly online

Cable assembly electrical engineering

Cable harness production

Cable harness manufacturer automotive

Electrical assemblies

Drone cable assembly

OEM manufacturer for assemblies and devices

Supplier and development partner for medicine, automotive and industry

in-Tec Bensheim is an OEM manufacturer for the production of ready-to-install components, assemblies and complete devices. Cable assembly and the production of media-carrying hose systems are also part of the portfolio.

As a contract manufacturer, we deliver high quality OEM products to our customers. As an experienced full-service supplier, we are your contact for production and development.

Our team offers OEM manufacturing for …

- Prototypes

- Components

- Component assembly

- Complete devices

OEM contract manufacturing for various industries

Our customers come from well-known companies in the automotive sector, medical technology and industry. We also supply tailor-made solutions according to customer requirements for other industries, such as automation. From mechanical assemblies and medical tubes to complete OEM devices (complete devices).

What is an OEM?

OEM is the abbreviation for the English term “Original equipment manufacturer”. Original equipment manufacturers are often associated with the automotive sector. However, as an OEM and system supplier, we supply numerous industries. We supply our clients with components, assemblies and devices and install or use them directly in their products.

Your advantages with us as an OEM manufacturer

We operate as an OEM manufacturer on the international market. The OEM products are developed and manufactured at our location in Bensheim, Germany.

We work with our customers and partners on a trusting and professional basis. We are more than just a supplier. Together we determine the technical requirements, consider feasibility, raise potential for improvement and support the development - up to series readiness and series production. You can also put them in our experienced hands.

We work with our customers and partners on a trusting and professional basis. We are more than just a supplier. Together we determine the technical requirements, consider feasibility, raise potential for improvement and support the development - up to series readiness and series production. You can also put them in our experienced hands.

- Product customisation capability: Specific modifications and customisations according to customer requirements, taking into account the OEM design, where products are developed while maintaining the brand identity and corporate design of the brand owner.

- Comprehensive services: Including logistics, parts procurement and storage.

- Efficient use of resources: Support that allows customers to focus on their core business.

- Certified: Demonstrates commitment to quality and safety.

- Compliance: Products meet the highest quality standards and comply with the relevant requirements of your business.

OEM services

As a company, you are constantly facing challenges in production and development to maintain your competitiveness. An OEM manufacturer, like us, can play a crucial role in this by providing customised, efficient and high-quality solutions.

Find out more about the company in-Tec Bensheim and its services for component assembly and cable assembly.

A partner for manufacturing, development and logistics

As an OEM manufacturer, we offer you comprehensive services in the areas of manufacturing, development and logistics. Our goal is to provide you with the most efficient and effective solution for your production requirements. With our many years of experience and specialised expertise as an OEM manufacturer, we can help you realise your products from conception to delivery.

Cost savings in terms of personnel and infrastructure

By working with an OEM manufacturer, you can achieve significant savings in terms of personnel and infrastructure. We take responsibility for the technical and logistical aspects of production, leaving you free to focus on your core business. With our support, you can make the most of your operational resources while reducing your operating costs.

Know-how and knowledge building with a competent partner

An important advantage of working with an OEM manufacturer is the exchange of knowledge and experience. We have in-depth expertise in product development, manufacturing and quality management that we are happy to share with you. In this way, you can improve your products, strengthen your competitive advantage and consolidate your market position.

More flexibility even for short-term and unexpected requirements

As an OEM manufacturer, we are prepared to respond to unexpected challenges and short-term requirements. We have flexible production processes and systems that enable us to respond quickly and efficiently to changes in your business environment. Whether you have a sudden increase in demand or need to make a product change, we are ready to help.

Process reliability and quality management

Quality and reliability are the cornerstones of our work as an OEM manufacturer. We implement quality control procedures and use technology to ensure that every product we manufacture meets the highest quality standards. With our commitment to process safety and quality management, you can be confident that your products will consistently meet your customers' expectations.

OEM process: How does OEM work at in-Tec Bensheim?

As an OEM partner, we are always flexible, but we also trust in the necessary processes to make OEM outsourcing a success. Together we develop an understanding of the project. We will show you a process using the example of a component for a dental device.

1. Needs assessment: You as our customer identify a need for a component in your medical technology company. We hold an initial meeting to discuss your specific requirements and expectations. The process and budget are also discussed.

2. Product development: Depending on how far the product process has progressed, we develop an initial product concept or refine the existing one. This concept could be a technical drawing or a detailed design, which is then discussed and optimised with you until we agree on a final specification.

3. Prototyping: once the product development is complete, we make one or more prototypes of the component. These prototypes allow you to examine the product and provide feedback.

4. Mass production: after successful prototype testing and any adjustments, we start mass production of your component. We ensure that every product that leaves our manufacturing facility meets the highest quality standards.

5. Delivery: Once mass production is complete, we deliver the finished media-carrying hoses directly to your desired location. We ensure that delivery is on time and in line with your logistical requirements.